Pipe Soundproofing

Pipe soundproofing is a crucial factor in ensuring acoustic comfort in buildings, as noise from sewage and water systems can affect the quality of life of the inhabitants. Effective soundproofing requires understanding the causes of noise, selecting appropriate materials, and applying correct installation techniques.

Causes of Noise in Pipes

The main sources of noise in pipes include:

- Flow of Fluids: The movement of water, especially at high speeds, can cause noise due to friction with the pipe walls.

- Vibrations: Vibrations from machinery, such as pumps or HVAC systems, can be transferred through the pipes, causing noise.

- Thermal Expansion: Temperature changes cause expansion and contraction of the pipes, generating sounds.

Soundproofing Techniques

For effective pipe soundproofing, the following practices are recommended:

- Use of Soundproofing Materials:

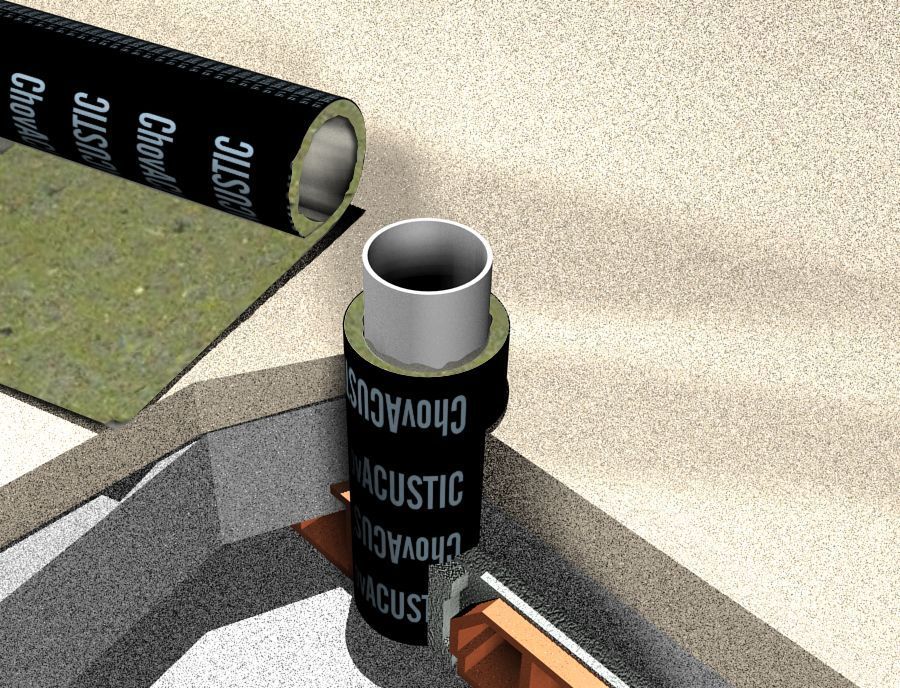

- Wrapping the pipes with high-density soundproofing membranes drastically reduces the transmission of airborne noise.

- Using flexible, absorbent layers reduces vibration propagation.

- Applying special soundproofing tapes at the joints of soundproof pipes offers additional noise and loss reduction.

- Double application of soundproofing membranes at pipe direction changes is necessary (where avoiding it is not feasible).

- Anti-vibration Support:

- Pipes should be secured with supports that include special anti-vibration inserts to prevent sound bridges between the pipes and the building's structural elements.

- The supports should not be overly tight to allow natural expansion and contraction of the pipes without generating additional noise.

- In critical areas, such as where pipes pass through walls or slabs, elastomeric materials should be used to reduce vibration transfer from the pipes to the building's structural elements.

- Proper Network Design:

- Avoiding sharp bends and diameter changes reduces the turbulent flow of water, thereby limiting friction noise.

- Choosing pipes with a larger diameter slows down the water flow, reducing the intensity of the generated sound.

- Installing soundproof inserts or noise dampers at strategic points in the network helps in the overall reduction of noise.

Recommended Soundproofing Materials

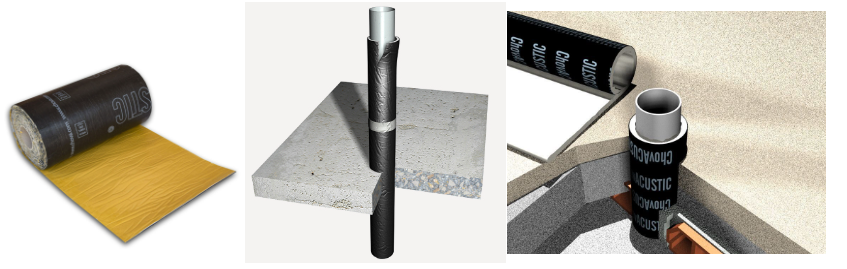

ELASTOBAND BAJANTES:

This is a high-density soundproofing membrane specifically designed to reduce noise caused by water flow in sewage pipes and air conditioning systems.

Composition:

- Polyethylene (PE): Provides durability and ease of installation.

- Elastomeric membrane: Offers excellent vibration absorption, reducing vibrational noise.

Advantages:

- Vibration absorption: Reduces structural noise transmitted through the pipes.

- High soundproofing performance: Suitable for areas requiring silence, such as residences and offices.

- Ease of installation: Flexible material that easily applies around pipes of various diameters.

- LEED certification

- Improves soundproofing by 8.6 dBA

Applications:

- Sewage pipes

- Air conditioning systems

- Ventilation systems

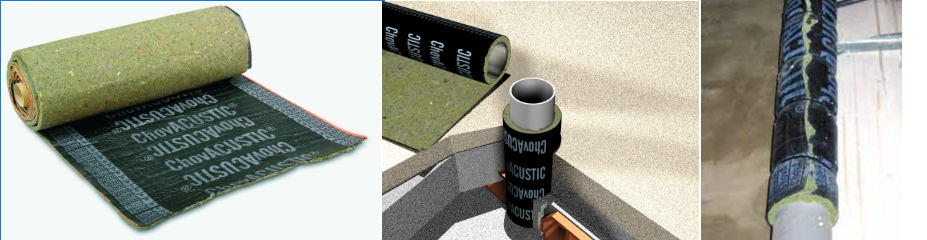

ChovaFieltex 35

ChovaFieltex 35 is an advanced soundproofing material that combines the durability of elastomers with the high absorption properties of fibers. It is designed to drastically reduce the noise generated by piping systems.

Composition:

- Elastomers: Provide flexibility and vibration absorption.

- High-absorption fibers: Contribute to the absorption of sound waves, offering superior soundproofing ability.

Advantages:

- High-temperature resistance: Ideal for systems where high temperatures are generated (e.g., hot water).

- Excellent noise reduction: Reduces both airborne and structural noise.

- Durability: A material with a long lifespan, even in demanding environments.

- LEED certification

- Improves soundproofing by 12.7 dBA

Applications:

- Plumbing installations

- Heating systems

Cover Sound Bit

Cover Sound Bit is a soundproofing material, reinforced with fibers, designed to reduce noise transmission in sewage pipes and plumbing installations.

Composition:

- Reinforced fibers: The fibers enhance the mechanical strength of the material and improve its soundproofing capability.

- Dense composition: Its composition provides excellent absorption of sound waves, effectively limiting noise transmission.

Advantages:

- Effective soundproofing: Reduces both airborne and structural noise.

- Durability: Despite the material's lightness, it has high strength and long-term performance.

- Ease of installation: Easily applied to pipes of various sizes and shapes.

Applications:

- Sewage pipes

- Plumbing installations

- Stormwater drainage systems

Importance of Soundproofing in the Construction Phase

Pipe soundproofing should be done during the construction phase of a building, as this allows us to address critical points, such as where a pipe passes through the concrete slab between floors. This ensures the optimal placement of soundproofing materials and prevents issues that may be difficult or expensive to fix later on.

Conclusion

Pipe soundproofing is essential for ensuring a quiet and comfortable living environment. The selection of appropriate materials and the application of correct techniques can significantly reduce the noise generated by piping systems, thereby improving the quality of life for the inhabitants.