Choosing the right anti-vibration materials is a critical factor for effective sound insulation and vibration protection in construction projects.

Anti-vibration pads, made from the innovative material Viscoren®, offer a range of advantages that make them an ideal solution for floating floors and anti-vibration machinery. It has been designed to maintain its original characteristics over time, providing durability and stability in a variety of conditions.

Technical Characteristics and Advantages of Viscoren®

Viscoren® is a material distinguished by its excellent resistance to harsh environmental conditions and its long-term performance.

Specifically, it offers the following advantages:

- UV resistance: It is an ideal choice for outdoor applications, as it maintains its stability and is not affected by exposure to the sun.

- Ozone resistance: It exhibits excellent ozone resistance, which makes the material resistant to deformation and wear.

- Chemical resistance: Offers good exposure behavior to a variety of chemical agents, making it suitable for applications in environments where various chemicals are present.

- 100% recyclable: The material is completely environmentally friendly as it can be completely recycled, reducing the environmental footprint.

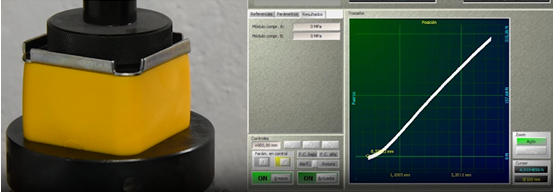

- Resonance Avoidance: Combines a very low natural damping frequency, achieving excellent levels of Anti-Vibration Protection.

- Competitive price: Despite its advanced capabilities, Viscoren®< /a> is offered at an extremely competitive price.

Advanced Durability and New Applications

The composition of Viscoren® ensures high resistance to various environmental factors, providing a solution to areas of application where traditional materials such as rubber would have limitations. The material significantly exceeds the lifetime and durability of conventional rubber, making it ideal for applications in demanding environments.

Furthermore, through specialized software, it is possible to choose the appropriate Anti-Vibration for each application. Depending on the requirements, such as the density, the thickness and the way of support, the maximum possible certified Anti-Vibration protection is ensured.

Floating Floor Application Example

A typical floating floor application using Viscoren® Anti-Vibration pads includes the following steps:

- Using Pads Viscoren® (60x60mm) for Anti-vibration base.

- Application of perimeter cut-off tape for anti-vibration protection.

- Installation of mineral wool for additional sound absorption.

- Layer with 19mm thick MDF panels for a stable surface.

- Application of nylon plastic sheet for moisture protection.

- Final coating with concrete (6 cm thick) or 20 mm thick fiber cement floorboard panels.

This combination of materials and techniques ensures excellent levels of anti-vibration protection, sound insulation and long-term durability.

Supported by Stop Sound Constructions

Stop Sound Constructions is available for any additional clarification and question regarding your needs in soundproofing solutions . Using its expertise and experience, it can offer customized solutions to meet your requirements for Shockproofing and Soundproofing.

Whether it is floating floors, or Anti-Vibration machines, Viscoren® and the solutions of Stop Sound Constructions offer reliability and efficiency, always with quality and long-term durability in mind.